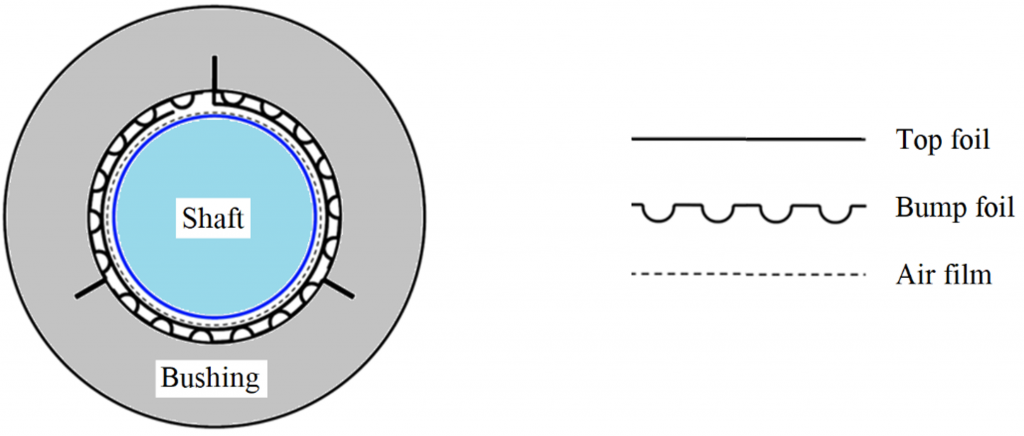

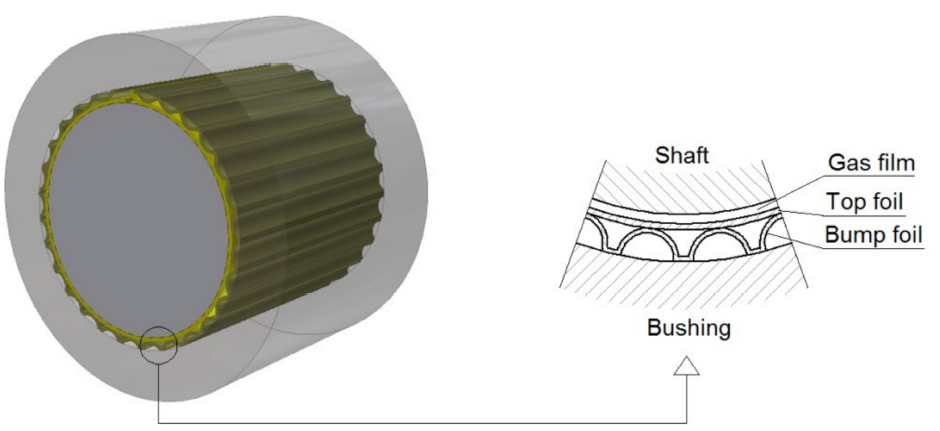

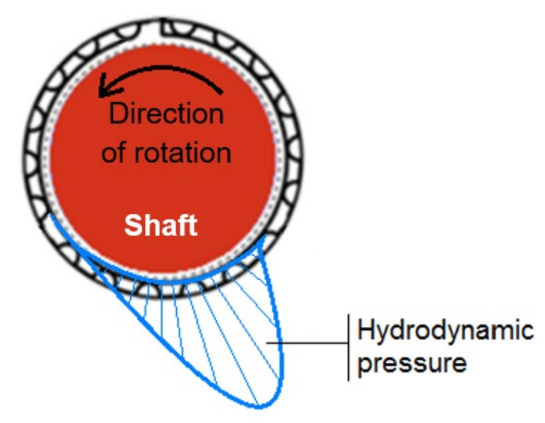

High-speed rotating machineries require specific engineering solutions to be implemented to support their shafts. Gas Foil Bearings (GFB)s are one of the bearings types that offer demanded functionalities because they can operate at a wide temperature range and very high rotational speed, up to hundreds of thousands rpm. The GFB’s capabilities result from its unique structure. In contrast to the oil based journal bearings, GFBs make use of air for lubrication purpose as schematically visualized in figure below. Complementary use of both air film and a set of specialized thin metallic foils enables extraordinary dynamic properties of the bearing, operating at almost maintenance free conditions, preferably with lightly-loaded shafts.