There have been completed several technological steps to create the described technical solution, including preparation of the sensing top foil, construction of tricuspid bushing shell and the bearing’s housing as well as final test bed assembly. Below, main components of the test rig are briefly characterized.

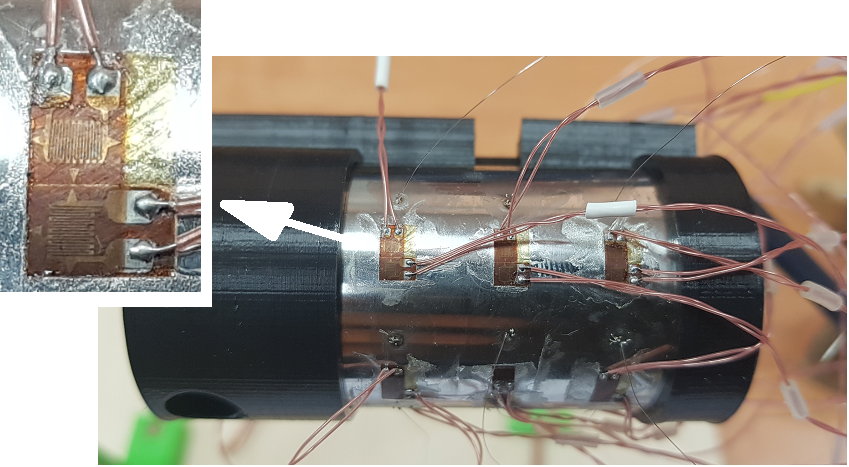

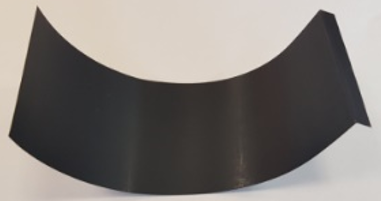

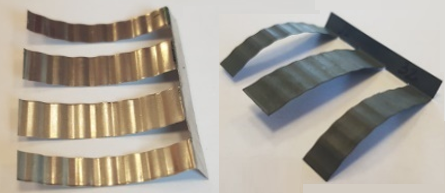

Figure below presents a multifunctional 0.1mm-thick top foil made of superalloy Inconel. It is held by the two 3D-printed side components to keep the nominal curvature of the top foil until it is mounted in the bearing’s bushing. The sets of platinum wires (0.1mm in diameter) are used to build thermocouples. Similarly, pairs of copper connections enable current flow through the strain gauges.

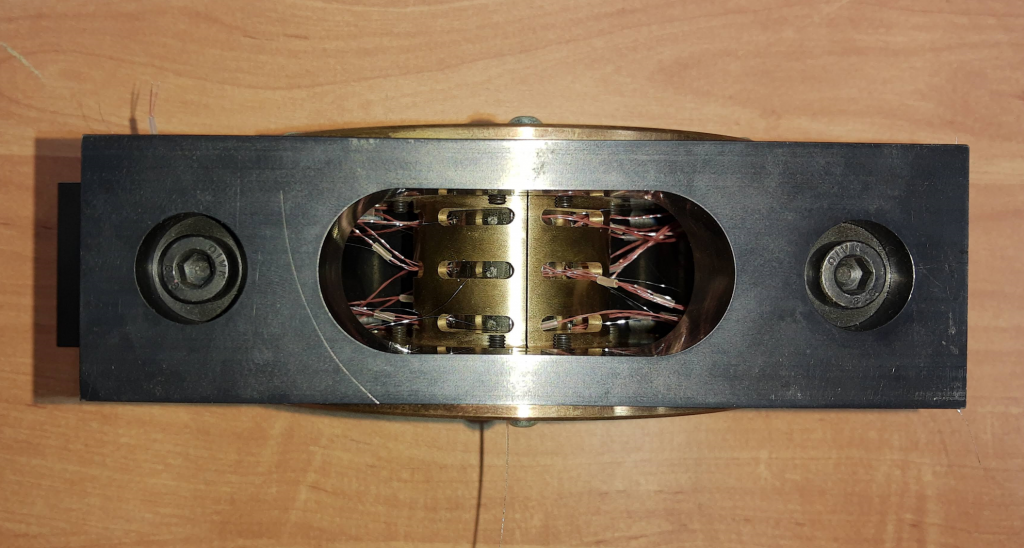

The top foil, after being equipped with strain gauges and thermocouples, is mounted in the GFB’s tricuspid bushing together with the three bump foils.

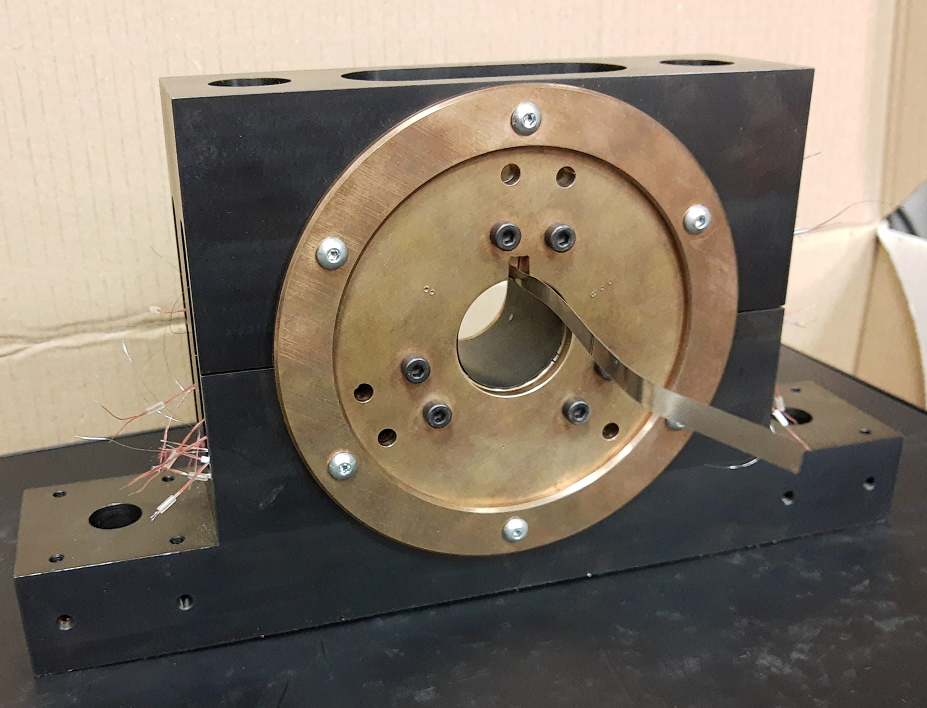

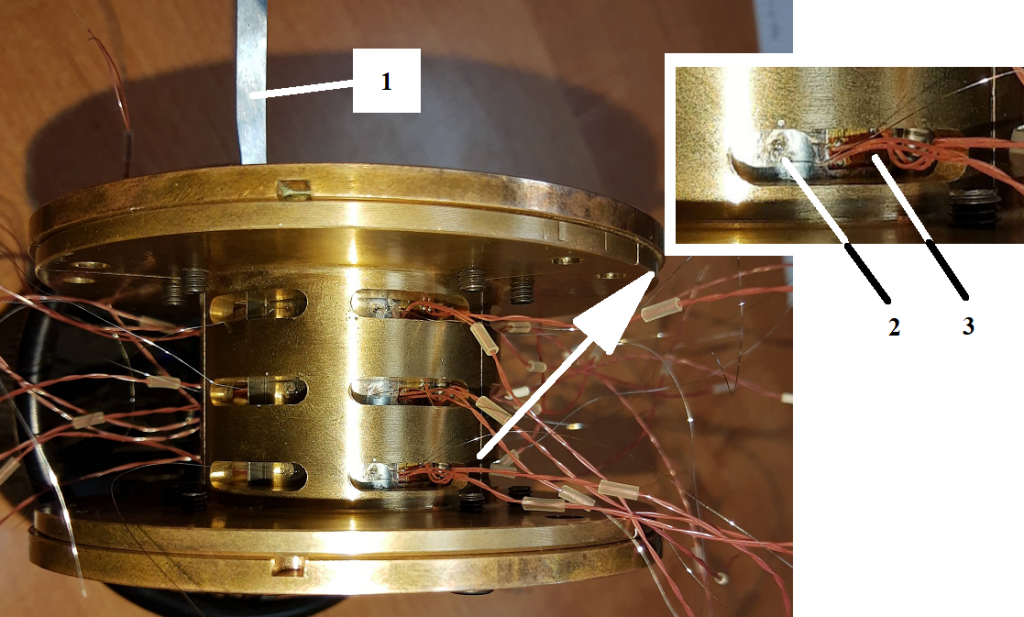

A complete assembly of the prototype bearing’s housing with installed bushing is shown below.